October 25, 2024 PS5 repair

PS5 SLIM drive trouble? See how I can fix it perfectly with 3D printing technology

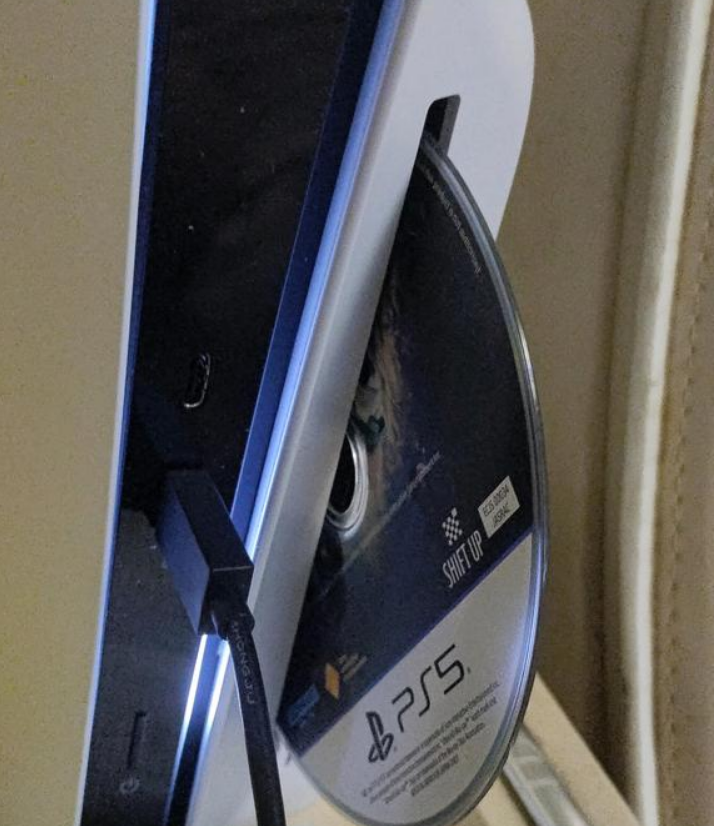

PS5 SLIM drive has serious problems. Firstly, the optical drive cannot read discs normally and makes clicking sounds. Specifically, the disc cannot be sucked into the optical drive. Even if it is forced in, it cannot be ejected.

I. Fault Phenomena

At this time, the optical drive is like a threshing machine, making continuous clicking sounds as if it is about to explode. At the same time, the host also prompts an optical drive error.

It should be noted that if a newly bought machine finds that it cannot suck the disc into the optical drive, generally, as long as the system version is updated, it will be fine. However, the situation I encountered was a mechanical failure. The disc has been sucked in, but the release mechanism jams it. Pushing hard, you can open the magnet and push the disc in. However, when ejecting the disc, it will still be jammed by the magnet release mechanism.

II. Fault Causes

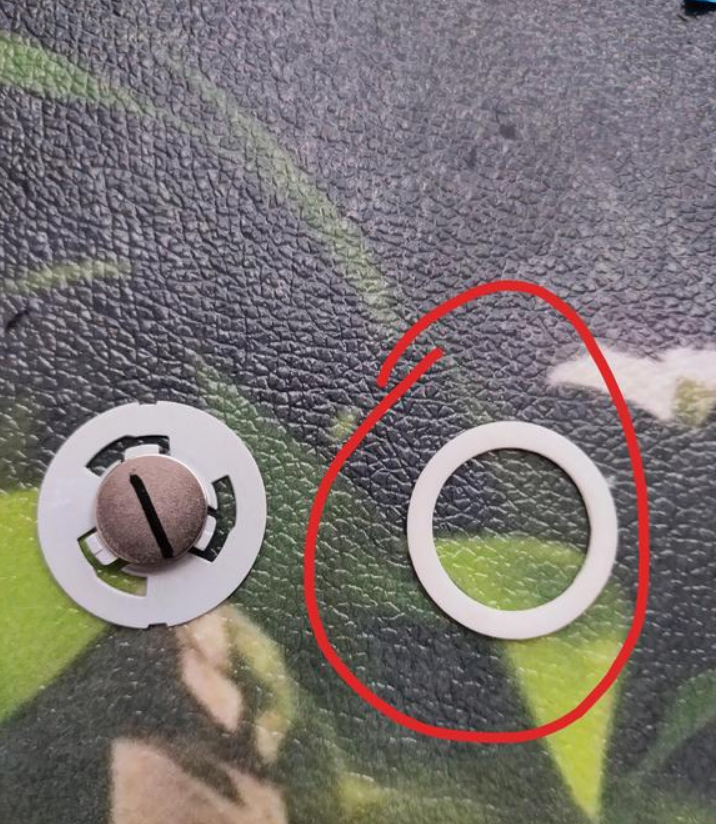

After taking out the drive of ps5 slim, it is found that the magnet of the optical drive cannot pop out, thus jamming the disc and preventing the disc from being sucked in and ejected. It is this circular metal in the picture, and there is a magnet inside.

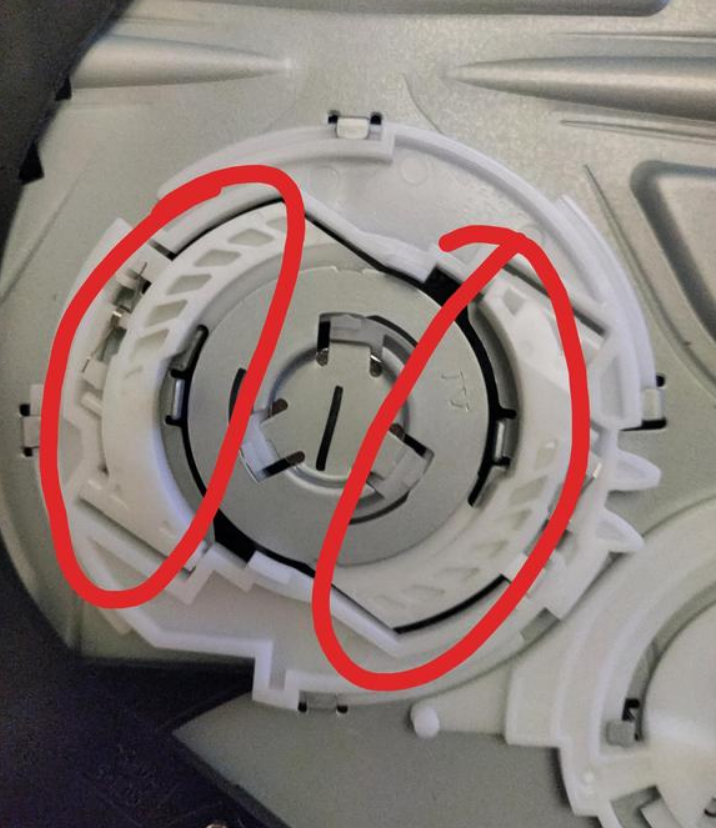

When the optical drive works, this magnet will attract the internal motor to hold the disc. When the optical drive sucks in and ejects the disc, the plastic on both sides will raise and lift out the magnet. At this time, the disc can be sucked in and ejected normally. Otherwise, it will be jammed.

The current problem is that this magnet cannot be released normally and is always in a closed state with the motor as long as it can be released normally when sucking in and ejecting. The optical drive mechanism has a magnet release action. But I don’t know if it is a quality control problem with my optical drive or a design problem with the PS5 slim disc drive. The magnet cannot be released normally after the mechanism performs the release action. Although there is a lifting and releasing action, the lifting amplitude is too small to release the magnet normally.

III. Solution

I came up with an idea. As long as the thickness of the metal where the magnet is located is increased, the lifting amplitude can be increased, and the magnet can be released normally. That is, the metal ring outlined in red is in direct contact with the plastic piece of the release mechanism.

Through 3D printing, print a hollow circular accessory and stick it on the metal piece to thicken it. This will increase the lifting stroke of the release mechanism when releasing the magnet and enable the magnet to be released normally.

The above is the circular part I made using 3D printing technology. Stick it on the metal piece with two-component strong glue, and then install the optical drive back. At this time, the optical drive can be used normally. The sucking in and ejecting of the disc are back to normal, and there is no more clicking sound.

IV. Views on the PS5 Slim Drive

Finally, let me talk about my views on this optical drive. I think the design of this optical drive is unreasonable. Even if the optical drive is normal when the new machine is obtained, after a long time of use, problems such as unsmooth sucking in and ejecting or jamming may occur.

On the one hand, the metal piece where the magnet is installed is too thin. On the other hand, the problem mainly lies in the two plastics of the release mechanism. These two plastics will be worn after long-term operation. That is, they will be thinned. The worn plastic mechanism will likely have problems releasing the magnet well.

Why do I say that this plastic component will be worn? After I disassembled the optical drive, I found that now the new optical drive has only been powered on and run a few times, and there are wear scratches on this plastic component. The reason is that the metal component is in direct contact with the plastic component, and the edge of the metal component has not been well polished. The working principle of these two components is that the mechanism raises the metal component by rotating the plastic component to release the magnet of the metal component. The friction between the plastic component and the metal interval, when the plastic component rotates, will wear the plastic component.

So, if netizens buy this machine, even if the optical drive is operating normally, those with hands-on ability can take out this metal component and polish the edge with sandpaper by themselves, which can effectively extend the service life and reduce the chance of damage. The mechanical structure and gears inside the optical drive are mainly made of plastic. Even the gear set on the motor is also made of plastic. In itself, this kind of plastic has good quality, and there is also self-lubrication between plastics. Therefore, the overall plastic mechanical structure and gear set are not likely to have problems. At present, the mechanical structure of this optical drive design, mainly the magnet metal component, is prone to problems (design defects and process defects). If possible, after polishing the metal component, you can also refer to my solution to increase the release stroke. In this way, as long as the optical drive motor is good for future use, there will be no problems such as not sucking in the disc, not ejecting the disc, or jamming the disc.