October 14, 2025 Westing News

Comprehensive Solutions for PS4 Analog Thumbstick Procurement and Installation Challenges

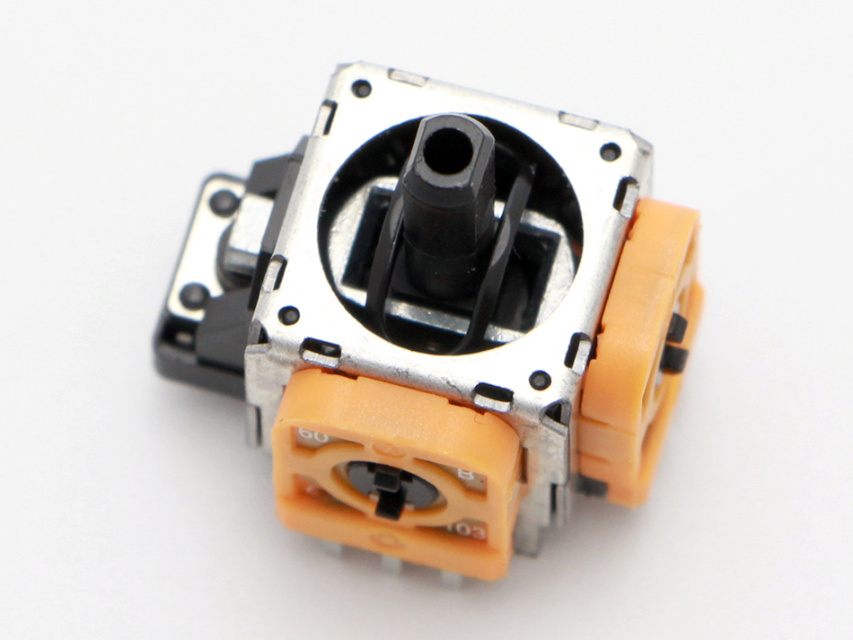

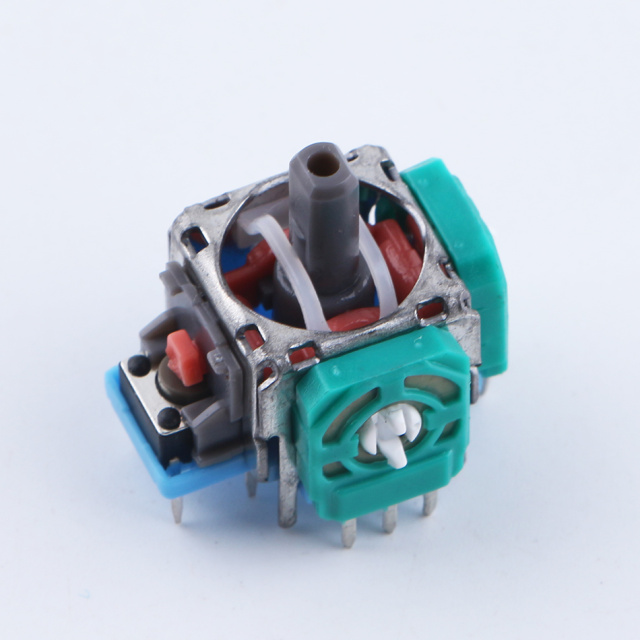

The gaming repair industry continues to face significant challenges in sourcing reliable analog thumbstick PS4 components while ensuring proper installation. A lot of repair shops and suppliers grapple with three core challenges: spotty quality control from manufacturers, not having access to detailed technical docs, and too little guidance when it comes to tricky repair jobs. These issues usually end up causing unhappy customers, repeated fixes down the line, and eventually, hurt their business’s reputation. Without standardized testing steps, a lot of components don’t measure up to the exact specs needed for different PS4 models—whether it’s the older CUH-1000 series or the newer CUH-7200 versions.

We tackle these challenges with an all-around system that pairs rigorously tested parts with detailed technical help. Every PS4 analog joystick we stock has gone through strict quality checks—including precision calibration tests, dead zone measurements, and durability checks that simulate over 2 million uses. We also give full technical docs that cover installation steps, compatibility tips, and troubleshooting steps for common problems like joystick drift or unresponsive inputs. This stuff’s made specifically to help both seasoned techs and people new to fixing PS4s get consistent, reliable results.

Case Study: Precision Play Repairs (Miami, USA)

This established repair service was experiencing a 25% return rate on their thumbstick replacements despite using components from a reputable supplier. After implementing our analog thumbstick PS4 components and technical support system, they achieved remarkable improvements within three months. Their return rate dropped to 3.2% while the average repair time decreased by 22 minutes per device.We gave them detailed install guides and calibration steps, and that helped them get their repair processes standardized across all five shops. Their customer satisfaction went up 38%—all because their repairs were now consistently good and reliable.

These case studies demonstrate that successful analog thumbstick PS4 repair services require addressing both component quality and technical knowledge gaps. If a repair shop can combine rigorously tested parts, solid technical support, and detailed operation manuals, it can solve the long-standing problems in the industry, stabilize business, and lay a foundation for long-term development.

2. Advanced Technical Support and Quality Assurance Systems

Fixing the analog thumbsticks on modern PS4 is more complex than just using good parts—you also need solid technical know-how and backup support. Lots of repair techs run into trouble with calibration steps, compatibility problems between different PS4 models, and figuring out hidden issues that mess with the thumbstick’s performance. These skill gaps usually end up causing repeat repairs, frustrated customers, and losing out on business—because clients will just go find a more reliable shop instead.

Our technical support setup lets us tackle these challenges with a bunch of linked-up resources. We’ve got detailed repair manuals that walk you through everything—from basic replacement steps to advanced calibration tricks. These manuals have specific how-tos for different PS4 models, pointing out the special needs and possible headaches for each version.

In the gaming repair industry, sustainable success needs more than just taking care of quick repair jobs—it also means earning a name for being reliable and knowing your stuff.

3. Building Long-term Success Through Reliable Components and Expert Guidance

Sustainable success in the gaming repair industry requires more than just addressing immediate repair needs—it demands building a reputation for reliability and expertise. Many repair businesses struggle with maintaining consistent quality across all their services, particularly when it comes to analog thumbstick PS4 replacements and calibrations.

The challenge is compounded by the varying quality of available components and the technical complexity of modern gaming controllers, requiring both reliable parts and expert knowledge to deliver satisfactory results.

Why choose us? The advantages are as follows:

- Precision-tested components with 0.3% defect rate

- Comprehensive technical documentation and video guides

- 24/7 technical support for complex repair scenarios

- Batch consistency across all shipments

- Certification documents for customer assurance

- Flexible ordering with 100-unit MOQ